Mkulu wapamwamba kuponyedwa zitsulo kuwombera ndi mkulu kuvala kukana

yambitsani

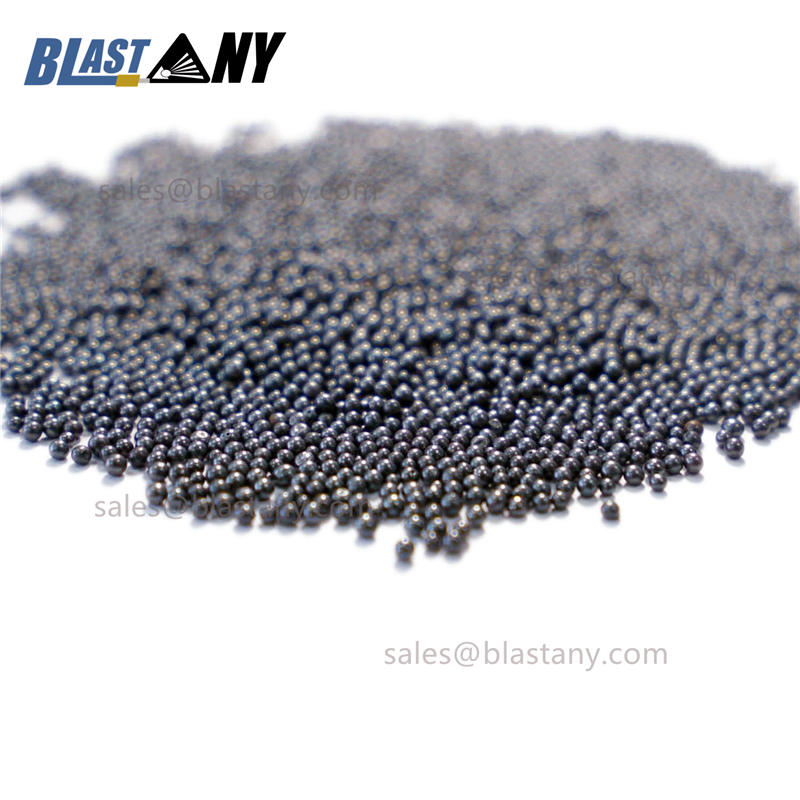

Junda Steel Shot amapangidwa ndi kusungunula zinyalala zosankhidwa mu ng'anjo yamagetsi yamagetsi. Kapangidwe ka chitsulo chosungunula kumawunikidwa ndikuwunikidwa mosamalitsa ndi spectrometer kuti apeze mafotokozedwe a SAE Standard. Chitsulo chosungunuka chimapangidwa ndi atomu ndikusandulika kukhala tinthu tating'onoting'ono ndipo kenako chimazimitsidwa ndikutenthedwa munjira yochizira kutentha kuti tipeze chinthu cholimba cha yunifolomu ndi microstructure, chowonetsedwa ndi kukula molingana ndi mafotokozedwe a SAE Standard.

Junda mafakitale kuwombera zitsulo lagawidwa zinayi, dziko muyezo kuponyedwa zitsulo kuwombera, munali chromium kuponyedwa zitsulo kuwombera, mapiritsi otsika mpweya zitsulo, zitsulo zosapanga dzimbiri, kuphatikizapo dziko muyezo kuponyedwa zitsulo kuwombera kwathunthu mogwirizana ndi dziko muyezo zofunika za zinthu zili mu kupanga, ndi chinthu cha chromium kuponyedwa zitsulo kuwombera, zachokera muyezo dziko la mipira zitsulo, kuwonjezera ferromanganese monga ferrowen chitsulo ndondomeko moyo wautali zinthu monga ferrowens moyo; Low mpweya zitsulo kuwombera ndondomeko kupanga ndi dziko muyezo kuwombera zitsulo, koma zopangira ndi otsika mpweya zitsulo, mpweya zili m'munsi; Kuwombera kwachitsulo chosapanga dzimbiri kumapangidwa ndi atomizing kupanga njira, zopangira ndi chitsulo chosapanga dzimbiri, 304, 430 chitsulo chosapanga dzimbiri ndi zina zotero.

Kuwombera kwamtunduwu kumapangidwira kugwiritsidwa ntchito pophulitsa ndi kuphulitsa popanikizika ndi mpweya woponderezedwa. Amagwiritsidwa ntchito pazitsulo zopanda chitsulo monga aluminium, alloys zinc, zitsulo zosapanga dzimbiri, mkuwa, mkuwa, mkuwa ...

Ndi ma grading ake osiyanasiyana, amagwiritsidwa ntchito kuyeretsa, kupukuta, kuphatikizira, kuloza ndikumaliza, pamitundu yonse, popanda kuipitsa pamwamba pake ndi fumbi lachitsulo lomwe limawonongeka ndikusintha mtundu wazitsulo zomwe zagwiritsidwa ntchito. kwa njira yokalamba ya marble ndi granite.

Kugwiritsa ntchito mafakitale

Kuwombera kwachitsulo

Kuwombera kwachitsulo kuyeretsa mchenga woponyera ndi kuwotchedwa - pamchenga wa kuponyera kuti pamwamba pakhale ukhondo wabwino komanso wovuta, kuti apindule ndi kukonza ndi kupaka.

Kuwombera kwachitsulo kwazitsulo zazitsulo zokonzekera pamwamba

Kuwombera kwachitsulo kumatsuka khungu la oxide, dzimbiri ndi zonyansa zina powombera Kuphulika, kenako kugwiritsa ntchito vacuum chotsukira kapena mpweya woyeretsedwa kuti mutsuke zinthu zachitsulo.

Zowombera zitsulo zomwe zimagwiritsidwa ntchito pamakina a Engineering

Kuwombera kwachitsulo komwe kumagwiritsidwa ntchito poyeretsa Makina kumatha kuchotsa dzimbiri, kuwotcherera slag, ndi khungu la okusayidi, kuthetsa nkhawa zowotcherera, ndikuwonjezera mphamvu zomangira pakati pakuchotsa dzimbiri ndi zitsulo, motero kumakulitsa kwambiri kutayika kwa makina opangira makina.

Chitsulo chowombera kukula kwa Stainless steel plate

Kuti akwaniritse chithandizo chaukhondo, chowala, chowotcha chowoneka bwino cha mbale yachitsulo chosapanga dzimbiri, iyenera kusankha zida zoyenera zomangira kuti zichotse sikelo pazitsulo zozizira zosapanga dzimbiri.

Malinga ndi magiredi osiyanasiyana, chitsulo chosapanga dzimbiri chimafunika kusankha ma abrasives osiyanasiyana m'mimba mwake ndikufanana ndi kukonzedwa. Poyerekeza ndi njira yachikhalidwe yamankhwala, imatha kuchepetsa mtengo woyeretsa ndikukwaniritsa kupanga zobiriwira.

Kuwombera kwachitsulo kuphulitsa media kwa Pipeline anti-corrosion

Mapaipi achitsulo amafunikira chithandizo chapamwamba kuti alimbikitse kukana kwa dzimbiri. Ndi kuwombera chitsulo, kuphulika TV kupukuta, kuyeretsa ndi kuchotsa okusayidi ndi ZOWONJEZERA kukwaniritsa anapempha dzimbiri kuchotsa kalasi ndi kuya kwa njere, osati kuyeretsa pamwamba komanso kukhutiritsa adhesion pakati zitsulo chitoliro ndi ❖ kuyanika, kukwaniritsa zabwino odana ndi dzimbiri zotsatira.

Chitsulo chowombera peening kulimbitsa

Zigawo zachitsulo zomwe zimagwira ntchito mozungulira mozungulira komanso zomwe zimakhudzidwa ndi kupsinjika panjinga zimafunikira kuwomberedwa kolimbitsa thupi kuti mukhale ndi moyo wotopa.

Kuponya zitsulo kuwombera Magawo a Ntchito

zitsulo akatemera peening makamaka ntchito kulimbikitsa processing wa mbali zofunika monga helical kasupe, tsamba kasupe, mipiringidzo zopotoka, zida, kufala mbali, kubala, cam kutsinde, opindika chitsulo cholimba, cholumikizira ndodo ndi zina zotero. Ndege ikatera, zida zokwerera ziyenera kupirira zovuta zomwe zimafunikira kuwomberedwa pafupipafupi. Mapiko amafunikiranso chithandizo cha periodic stress release.

Magawo aukadaulo

| Ntchito | Miyezo Yadziko | Ubwino | |

| Chemical composition% | C | 0.85-1.20 | 0.85-1.0 |

| Si | 0.40-1.20 | 0.70-1.0 | |

| Mn | 0.60-1.20 | 0.75-1.0 | |

| S | <0.05 | <0.030 | |

| P | <0.05 | <0.030 | |

| Kuuma | mfuti yachitsulo | HRC40-50 HRC55-62 | HRC44-48 HRC58-62 |

| Kuchulukana | mfuti yachitsulo | ≥7.20 g/cm3 | 7.4g/cm3 |

| Microstructure | Kutentha kwa Martensite kapena Troostite | Bungwe la Tempered Martensite Bainite Composite | |

| Maonekedwe | Chozungulira Zopanda kanthu <10% Mng'alu wa particle <15% | Chozungulira Zopanda kanthu <5% Mng'alu wa particle <10% | |

| Mtundu | S70, S110, S170, S230, S280, S330, S390, S460, S550, S660, S780 | ||

| Kulongedza | Toni iliyonse mu Pallet yosiyana ndipo tani iliyonse imagawidwa m'mapaketi a 25KG. | ||

| Kukhalitsa | 2500 ~ 2800 nthawi | ||

| Kuchulukana | 7.4g/cm3 | ||

| Diameter | 0.2mm, 0.3mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.4mm, 1.7mm, 2.0mm, 2.5mm | ||

| Mapulogalamu | 1. Kutsuka zophulika: Kugwiritsidwa ntchito poyeretsa kuphulika kwa kuponyera, kufa-kuponya, kufota; Kuchotsa mchenga wa kuponyera, mbale zitsulo, H mtundu zitsulo, kapangidwe zitsulo. 2. Kuchotsa dzimbiri: Kuchotsa dzimbiri kwa kuponyera, kupanga, mbale yachitsulo, chitsulo chamtundu wa H, kapangidwe kazitsulo. 3. Kuwomberedwa peening: kuwomberedwa peening wa zida, kutentha mankhwala mbali. 4. Kuwombera Kuwombera: Kuwombera kwachitsulo chambiri, bolodi la ngalawa, bolodi lachitsulo, chuma chachitsulo, kapangidwe kazitsulo. 5. Kuchiza koyambirira: Kukonzekera koyambirira kwa pamwamba, bolodi lachitsulo, chitsulo chambiri, kapangidwe kazitsulo, musanapange zojambula kapena zokutira. | ||

Kukula Kwa Kuwombera Kwachitsulo

| SAE J444 Standard Steel shot | Screen No. | In | Kukula kwazenera | |||||||||||

| S930 | S780 | S660 | S550 | S460 | S390 | S330 | S280 | S230 | S170 | S110 | S70 | |||

| ZONSE zadutsa | 6 | 0.132 | 3.35 | |||||||||||

| Zonse Zapita | 7 | 0.111 | 2.8 | |||||||||||

| 90% mphindi | Zonse Zapita | 8 | 0.0937 | 2.36 | ||||||||||

| 97% mphindi | 85% mphindi | Zonse Zapita | Zonse Zapita | 10 | 0.0787 | 2 | ||||||||

| 97% mphindi | 85% mphindi | 5% max | Zonse Zapita | 12 | 0.0661 | 1.7 | ||||||||

| 97% mphindi | 85% mphindi | 5% max | Zonse Zapita | 14 | 0.0555 | 1.4 | ||||||||

| 97% mphindi | 85% mphindi | 5% max | Zonse Zapita | 16 | 0.0469 | 1.18 | ||||||||

| 96% mphindi | 85% mphindi | 5% max | Zonse Zapita | 18 | 0.0394 | 1 | ||||||||

| 96% mphindi | 85% mphindi | 10% max | Zonse Zapita | 20 | 0.0331 | 0.85 | ||||||||

| 96% mphindi | 85% mphindi | 10% max | 25 | 0.028 | 0.71 | |||||||||

| 96% mphindi | 85% mphindi | Zonse Zapita | 30 | 0.023 | 0.6 | |||||||||

| 97% mphindi | 10% max | 35 | 0.0197 | 0.5 | ||||||||||

| 85% mphindi | Zonse Zapita | 40 | 0.0165 | 0.425 | ||||||||||

| 97% mphindi | 10% max | 45 | 0.0138 | 0.355 | ||||||||||

| 85% mphindi | 50 | 0.0117 | 0.3 | |||||||||||

| 90% min | 85% mphindi | 80 | 0.007 | 0.18 | ||||||||||

| 90% min | 120 | 0.0049 | 0.125 | |||||||||||

| 200 | 0.0029 | 0.075 | ||||||||||||

| 2.8 | 2.5 | 2 | 1.7 | 1.4 | 1.2 | 1 | 0.8 | 0.6 | 0.4 | 0.3 | 0.2 | GB | ||

Masitepe Opanga

Zopangira

Kupanga

Kuyanika

Kuwunika

Kusankha

Kutentha

Kuwunika

Phukusi

Magulu azinthu