AISI1010/1015/1085 Mpira wachitsulo wokwera / wochepa wa kaboni 0.8 mm - 50.8 mm Mpira wachitsulo wa Mpweya wa zitsulo zonyamula njinga

Mafotokozedwe Akatundu

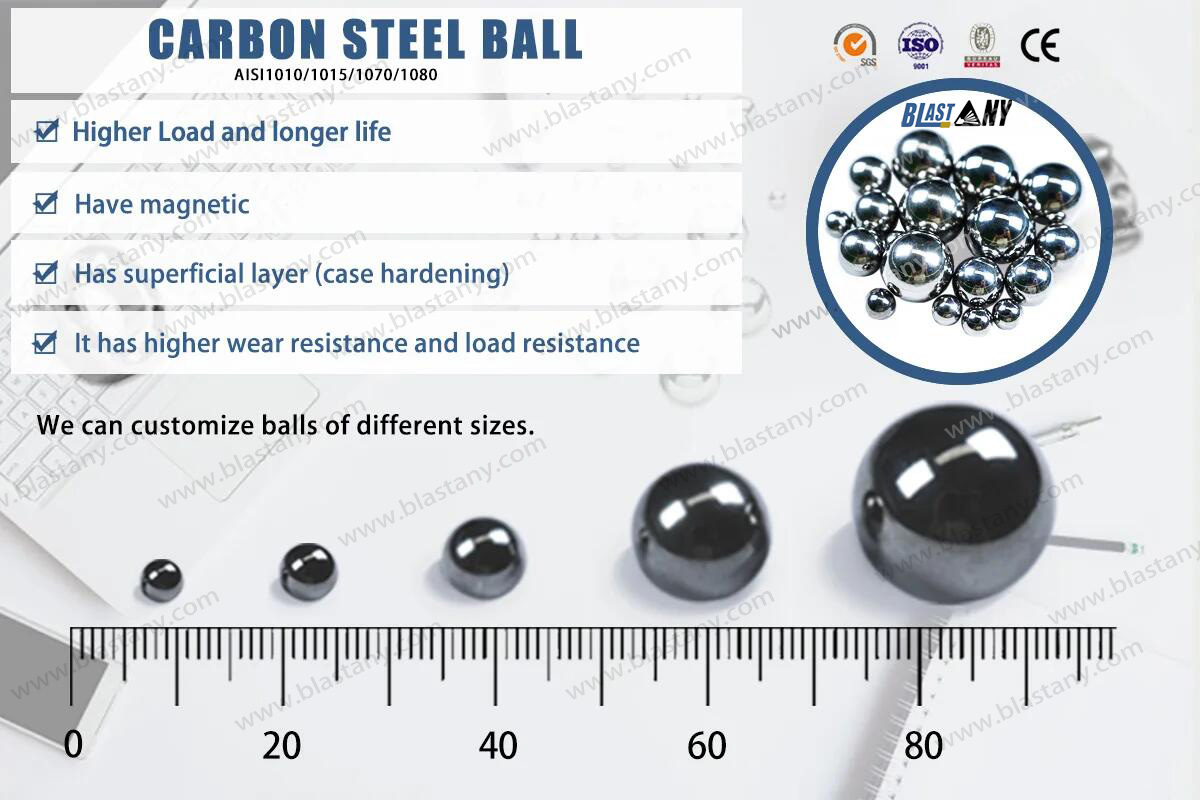

Mpira Wotsika wa Carbon Steel.

| Zakuthupi | AISI1010/1015 |

| Size Range | 0.8mm-50.8mm |

| Gulu | G100-G1000 |

| Kuuma | HRC: 55-65 |

Mafotokozedwe Akatundu

Mawonekedwe:

ali ndi maginito, Mipira ya Carbon Steel ili ndi wosanjikiza wowoneka bwino (wowumitsa milandu), pomwe gawo lamkati la mpirawo limakhalabe lofewa lachitsulo ndi ferrite, phukusi nthawi zambiri ndi mafuta. Nthawi zambiri electroplating ikakhala kunja, imatha kukutidwa ndi zinki, golide, faifi tambala, chrome ndi zina zotero. kukhala ndi ntchito zotsutsana ndi kuvala zolimba .Kufanizira: kuvala-kukana ndi kuuma sikuli bwino kuposa kunyamula mpira wachitsulo ( The HRC ya GCr15 zitsulo mpira ndi 60- 66 ): kotero, moyo ndi waufupi kwambiri.

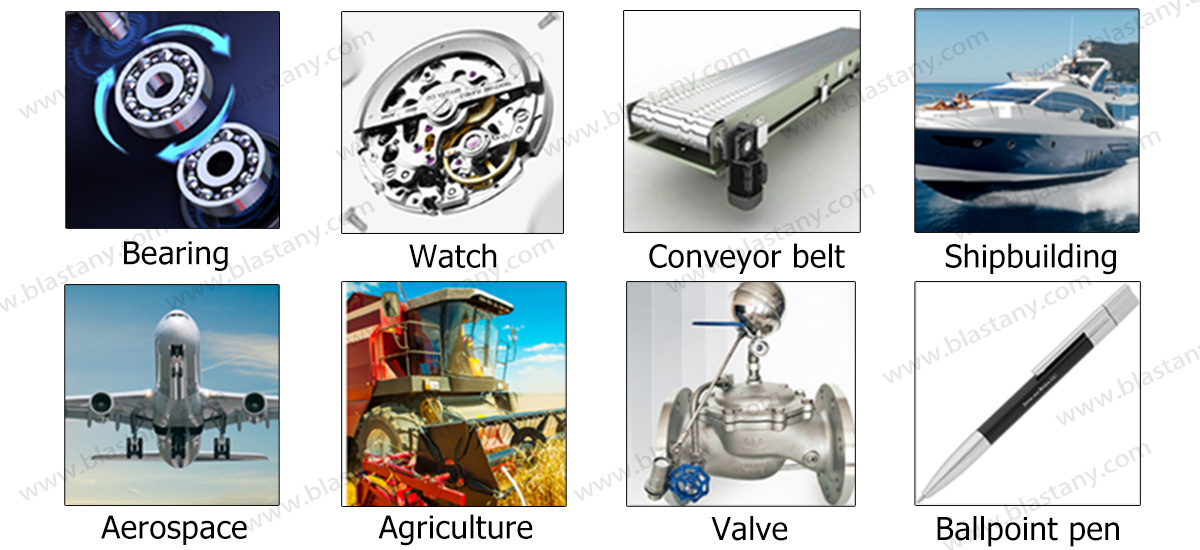

Ntchito:

1010/1015 mpweya zitsulo mpira ndi wamba zitsulo mpira, ali mtengo otsika, mwatsatanetsatane mkulu ndi ntchito lonse. Amagwiritsidwa ntchito panjinga, mayendedwe, gudumu launyolo, craftwork, alumali, mpira wosunthika, zikwama, zida zazing'ono, zitha kugwiritsidwanso ntchito kupaka ma medium.Castors, Dressers 'Bearings, Locks, Oilers And Grease Cups, Skates.drawers Slides And Window Rolling Bearings, Zoseweretsa, Mafinyiro Ndi Matupi.

| MTUNDU WA ZIPANGIZO | C | Si | Mn | P (MAX.) | S (MAX.) |

| AISI 1010 (C10) | 0.08-0.13 | 0.10-0.35 | 0.30-0.60 | 0.04 | 0.05 |

| AISI 1015 (C15) | 0.12-0.18 | 0.10-0.35 | 0.30-0.60 | 0.04 | 0.05 |

Mpira Wachitsulo Wapamwamba wa Carbon

| Zakuthupi | AISI1085 |

| Size Range | 2mm-25.4mm |

| Gulu | G100-G1000 |

| Kuuma | HRC 50-60 |

Mafotokozedwe Akatundu

Mawonekedwe:

AISI1070/1080 Mipira ya Zitsulo za Carbon, & Mipira yachitsulo yokwera kaboni ili ndi mwayi wodabwitsa potengera kuuma kwathunthu, komwe kuli pafupifupi 60/62 HRC ndipo imapereka kukana kwamphamvu komanso kukana kunyamula poyerekeza ndi mipira wamba yachitsulo yolimba ya carbon.

(1)Kulimba mtima

(2) Kuchepetsa kukana kuwononga kuwononga

(3) Katundu Wapamwamba ndi moyo wautali kuposa mpira wochepa wa carbon zitsulo

Ntchito:

Zipangizo zanjinga, mayendedwe amipira ya mipando, zowongolera, malamba onyamula, mawilo olemetsa, zida zothandizira mpira. Zotengera zolondola pang'ono, zida zanjinga & zamagalimoto, zonyamulira, ma skates, makina opukutira ndi mphero, mayendedwe otsika kwambiri.

| MTUNDU WA ZIPANGIZO | C | Si | Mn | P (MAX.) | S (MAX.) |

| AISI 1070 (C70) | 0.65-0.70 | 0.10-0.30 | 0.60-0.90 | 0.04 | 0.05 |

| AISI 1085 (C85) | 0.80-0.94 | 0.10-0.30 | 0.70-1.00 | 0.04 | 0.05 |

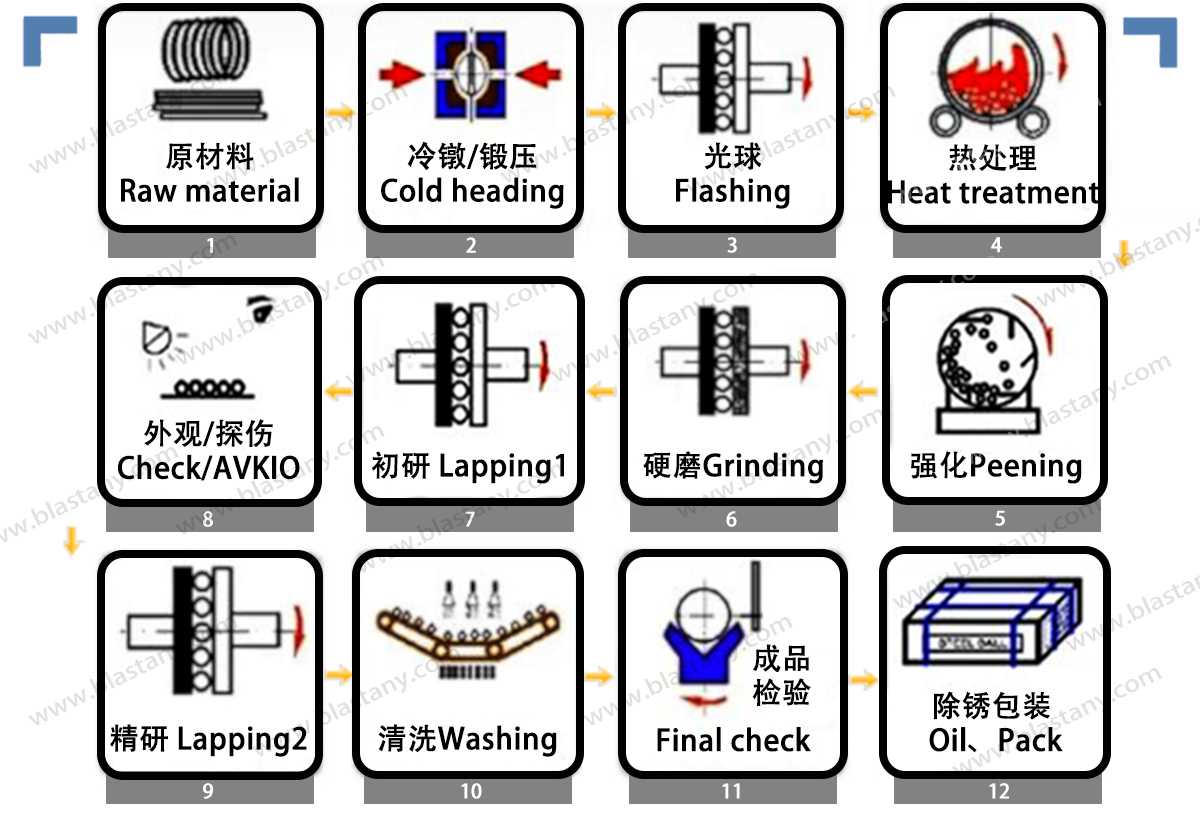

Njira yopanga

Njira Yopangira Zampira Wa Precision

1.Law Nkhani

Kumayambiriro kwake, mpira umayamba mu mawonekedwe a waya kapena ndodo. Kuwongolera kwaubwino kumadutsa pakuyezetsa zitsulo kuti zitsimikizire kuti zida zake zili m'malo ovomerezeka.

2.Mutu

Pambuyo poyang'ana zinthu zopangira, zimadyetsedwa kudzera pamutu wothamanga kwambiri. Izi zimapanga mipira yovuta kwambiri.

3.Kuthwanima

Kuthwanimako kumatsuka mipira yamutu kuti ikhale yosalala bwino.

4.Kuchiza Kutentha

Njira yotentha kwambiri yomwe mipira yowala imayikidwa mu uvuni wa mafakitale. Izi zimaumitsa mpira.

5.Kupera

Mpirawo umaphwanyidwa molingana ndi kukula kwa mpira womaliza.

6.Kugona

Kuthamanga kwa mpira kumaufikitsa pamlingo womaliza womwe ukufunidwa. Iyi ndiye njira yomaliza yopangira ndipo imapangitsa mpira kukhala wololera.

7.Kuyendera komaliza

Mpira umayesedwa ndendende ndikuwunikiridwa ndi Quality Control kuti muwonetsetse kuti ndi wapamwamba kwambiri.

Magulu azinthu