10MM MPAKA 130MM Kuponyera Kugaya Media Steel Ball kwa Ball Mill Metal Mines ndi Zomera za Simenti

Mafotokozedwe Akatundu

Njira yopanga

Mpira woponyera, womwe umatchedwanso kuti mpira wogaya, umapangidwa kuchokera ku zitsulo, zitsulo zotayidwa, ndi zinyalala zina. Zida zomwe tazitchula pamwambazi ndi zosungunuka kwambiri ndipo zimayendetsa madzi mosalekeza pambuyo potenthedwa. Panthawi yosungunula, zinthu zambiri zachitsulo monga vanadium, chitsulo ndi manganese zimayamba kuwonjezeredwa ku mpweya wa flue kuti mukwaniritse zokolola zomwe mukufuna komanso zokonzedweratu. Zinthuzi zimatha kutsanulira chitsulo chosungunuka kwambiri mumzere wopangira makina opangira zitsulo.

Kugwiritsa ntchito

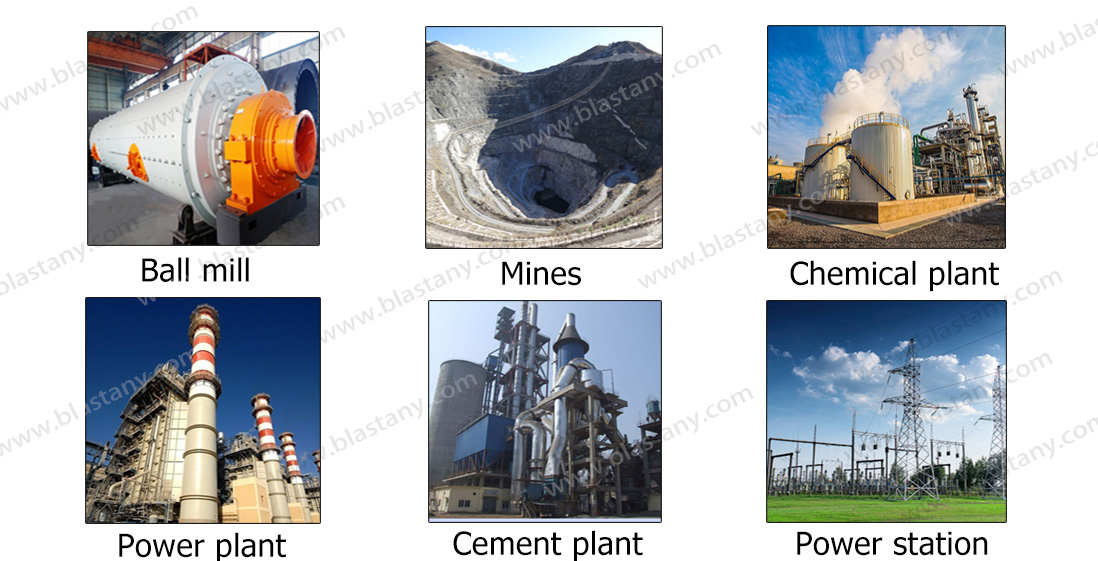

Casting Steel Ball itha kugwiritsidwa ntchito kwambiri pazinthu zosiyanasiyana, kuphatikiza

Fakitale ya mchenga wa silika/Fakitale ya simenti/malo opangira mankhwala/Nyengo zamphamvu/Migodi/malo opangira magetsi

/Chemical industries/Grinding mill/Ball mill/Coal mill

Chiyambi cha zinthu zopangira mpira wachitsulo

Mipira yachitsulo ya chrome ndi mipira yopukutira ya chromium yomwe ili ndi gawo lina la chromium, yomwe imagawidwa kukhala mipira yachitsulo ya chromium yapamwamba, mipira yachitsulo ya chromium yapakati ndi mipira yachitsulo yotsika ya chromium. Mipira yachitsulo ya chromium imagawidwa kukhala Mipira Yachitsulo Yapamwamba ya Chromium, Mipira Yachitsulo ya Chromium Yapakatikati ndi Mipira Yotsika ya Chromium Cast Steel. Ndi mbali ya kuuma mkulu, kuvala otsika, ndi otsika breakage, kuponyedwa zitsulo akupera mipira zimagwiritsa ntchito makampani simenti, makampani migodi, mafakitale metallurgical, makampani opanga magetsi ndi makampani zomangamanga.

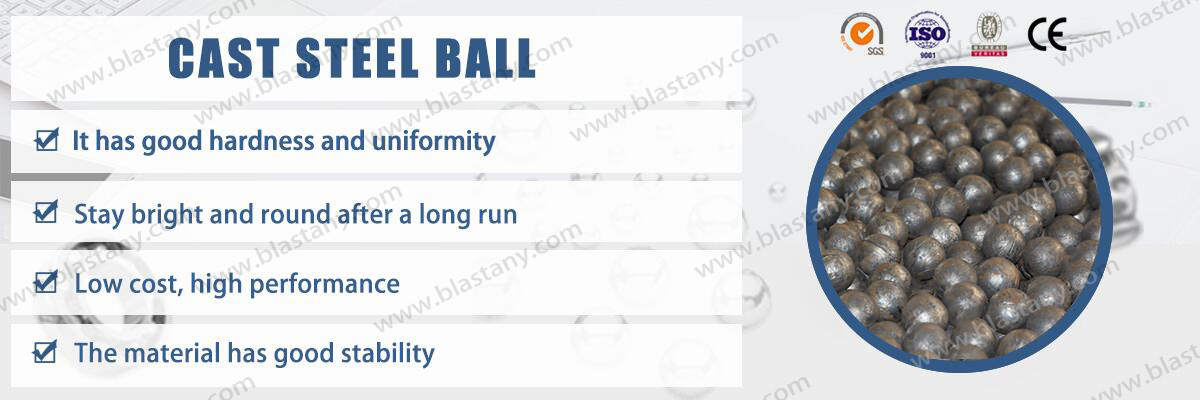

Mawonekedwe a Mpira Wachitsulo Wakuponya

1, The zipangizo zonse kubala zitsulo nyenyeswa, amene ali mkuwa, molybdenum, faifi tambala ndi zinthu zina zamtengo wapatali zitsulo, amene akhoza bwino kusintha masanjidwewo dongosolo la zitsulo mpira.

2, Zogulitsa zathu zimapangidwa ndi ng'anjo yamagetsi yamafupipafupi yomwe imatha kutsimikizira kukhazikika kwazinthuzo. Mipira ndiyosavuta kusenda ndikupunduka mukaigwiritsa ntchito. Ngakhale imatha kukhala yowala komanso yozungulira pakapita nthawi yayitali.

3, The zapamwamba kwambiri lalikulu basi kuzimitsa mafuta mzere kupanga anatengera kutentha mankhwala, amene amaonetsetsa kuuma wabwino ndi yunifolomu wa mankhwala.

Njira zitatu zopangira mipira yachitsulo

1. Njira zitatu zopangira mpira wachitsulo

Pali mitundu itatu ya njira zopangira mpira wachitsulo: kuponyera, kupangira, ndikugudubuza.

(1) Kuponya: Ubwino wa mipira yachitsulo choponyedwa makamaka zimatengera zomwe zili mu chromium. M'zaka zaposachedwa, kukwera mtengo kwa chromium, kuteteza chilengedwe, ndi zinthu zina zapangitsa kuti mtengo wa mipira yachitsulo ikhale yokwera mtengo.

(2) Kupanga: Kugwiritsa ntchito chitsulo chochuluka cha manganese monga zopangira, nyundo zopangira pneumatic ndi nkhungu za mpira zimagwiritsidwa ntchito kupanga mipira yachitsulo. Mipira yopangira zitsulo imakhala ndi kuphatikiza kokwanira kwa mpweya wambiri, manganese, chromium, ndi zinthu zina za aloyi, ndipo imakhala ndi kuuma kwamphamvu pakupangira kutentha kwapang'onopang'ono, kusiyana pang'ono pakuuma pakati pamkati ndi kunja, ndi kusiyana kwa phindu, zomwe zimapangitsa mipira yonyezimira kukhala yamphamvu kuposa mipira yoponyedwa.

(3) Kugudubuza: Pogwiritsa ntchito mipiringidzo yachitsulo ya manganese ngati zida zopangira, mipira yachitsulo imapangidwa ndi mphero ya skew yokhala ndi zodzigudubuza zozungulira.

| Kanthu | Mapangidwe a Chemical (%) | |||||||||

| C | Si | Mn | Cr | P | S | Mo | Cu | Ni | ||

| Chrome kwambiri kuponya mipira ya gri nding | ZQCr12 | 2.0-3.0 | 0.3-1.2 | 0.2-1.0 | 11-13 | ≤0.10 | ≤0.10 | 0-1.0 | 0-1.0 | 0-1.5 |

| ZQCr15 | 2.0-3.0 | 0.3-1.2 | 0.2-1.0 | 14-17 | ≤0.10 | ≤0.10 | 0-1.0 | 0-1.0 | 0-1.5 | |

| ZQCr20 | 2.0-2.8 | 0.3-1.0 | 0.2-1.0 | 18-22 | ≤0.10 | ≤0.08 | 0-2.0 | 0-1.0 | 0-1.5 | |

| ZQCr26 | 2.0-2.8 | 0.3-1.0 | 0.2-1.0 | 22-28 | ≤0.10 | ≤0.08 | 0-2.5 | 0-2.0 | 0-1.5 | |

| Mpira wapakati wa chrome wogaya ls | ZQCr7 | 2.0-3.2 | 0.3-1.5 | 0.2-1.0 | 6.0-10 | ≤0.10 | ≤0.08 | 0-1.0 | 0-0.8 | 0-1.5 |

| Mipira yopera ya chrome yotsika | ZQCr2 | 2.0-3.6 | 0.3-1.5 | 0.2-1.0 | 1.0-3.0 | ≤0.10 | ≤0.08 | 0-1.0 | 0-0.8 | |

Magawo apamwamba a chromium (High Chrome Ball Parameter)

| M'mimba mwake mwadzina | Kulemera kwa mpira umodzi mwa avareji(g) | kuchuluka / MT | Kuuma pamwamba(HRC) | Endurance impact test (Nthawi) |

| φ15 | 13.8 | 72549 | > 60 | > 10000 |

| φ17 | 20.1 | 49838 | > 10000 | |

| φ20 | 32.7 | 30607 | > 10000 | |

| φ25 | 64 | 15671 | > 10000 | |

| φ30 | 110 | 9069 pa | > 10000 | |

| φ40 | 261 | 3826 | > 10000 | |

| φ 50 | 510 | 1959 | > 10000 | |

| φ60 | 882 | 1134 | > 10000 | |

| φ70 | 1401 | 714 | > 10000 | |

| φ80 | 2091 | 478 | > 58 | > 10000 |

| φ90 | 2977 | 336 | > 10000 | |

| φ100 | 4084 | 245 | > 8000 | |

| φ120 | 7057 | 142 | > 8000 | |

| φ130 | 8740 | 115 | > 8000 |

Magulu azinthu